Paradigm 1

- Correlation between the main variables of additive manufacturing and of HIP sintering process and strength wear rate of prismatic or cylindrical specimens, also by the use of optical and scanning electron microscopy

- Optimization of post processing thermal cycles and of surface finish treatments for the achievement of the target mechanical performance and roughness

- Manufacturing and testing of bonded and FSW single-lap butt joints, to evaluate tensile strength before / after exposure to chemicals used for the cleaning and sanification of the machines

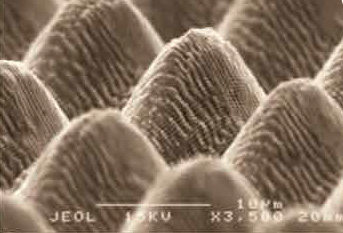

- Test with laser sources having different pulse duration (ns, ps, fs); parametric analysis of micro-nano surface topography by SEM-EDS and AFM.

- Characterization of the attitude of the treated surfaces to adhesion of liquids representatives of foods and of sanitizing agents by measurement of static and dynamic contact angle.

- Design and manufacturing procedures for the demonstrator; manufacturing; testing and validation

Paradigm 2

- Mathematical modeling and numerical simulation based on CFD

- Experimental campaign design (Design of Experiments, DoE)

- Development of the test circuit with the support of the companies involved in the project

- Testing of the apparata inserted in the circuit (scraped, corrugated and / or curved surface heat exchangers; twin-screw extruders for pasta)

- Identification of the heat transfer correlations for the types of equipment inserted in the circuit

- Development of original software tools for the design and optimization of the heat exchange apparata considered

- Design by simulation of innovative, high performance heat exchangers and twin-screw extruders

- Selection of the potentially most suitable system for in-line continuous monitoring of the homogenization degree of food emulsions (e.g. milk) among optical (turbidimeters), ultrasonic and viscosity measurement instruments

- Experimental identification, on food emulsions (milk), of the correlation between degree of homogenization and instrument signal

- Homogenization pressure control system based homogenization degree feedback signal

Classification of the new paradigms with respect to hygienic design requirements and quality of the processed food This activity is devoted to the evaluation of the compliance of the new paradigms relatively to the cleanability of the machines and to chemical and physical properties of the processed food.

- Assessment of conformity to hygienic design and cleanability requirements of new technological solutions according to current regulations and international guidelines (EHEDG); this activity will be done first at lab scale and then on the demonstrator.

- Evaluation of the quality of the processed food (chemical and physico-chemical parameters) compared to properties obtained by processing using conventional heat exchange apparata.

- Evaluation of the quality and the constancy of the degree of homogenization of food fluids with the new control system